Choose the country or territory you are in to see local content.

Quality and traceability for product safety

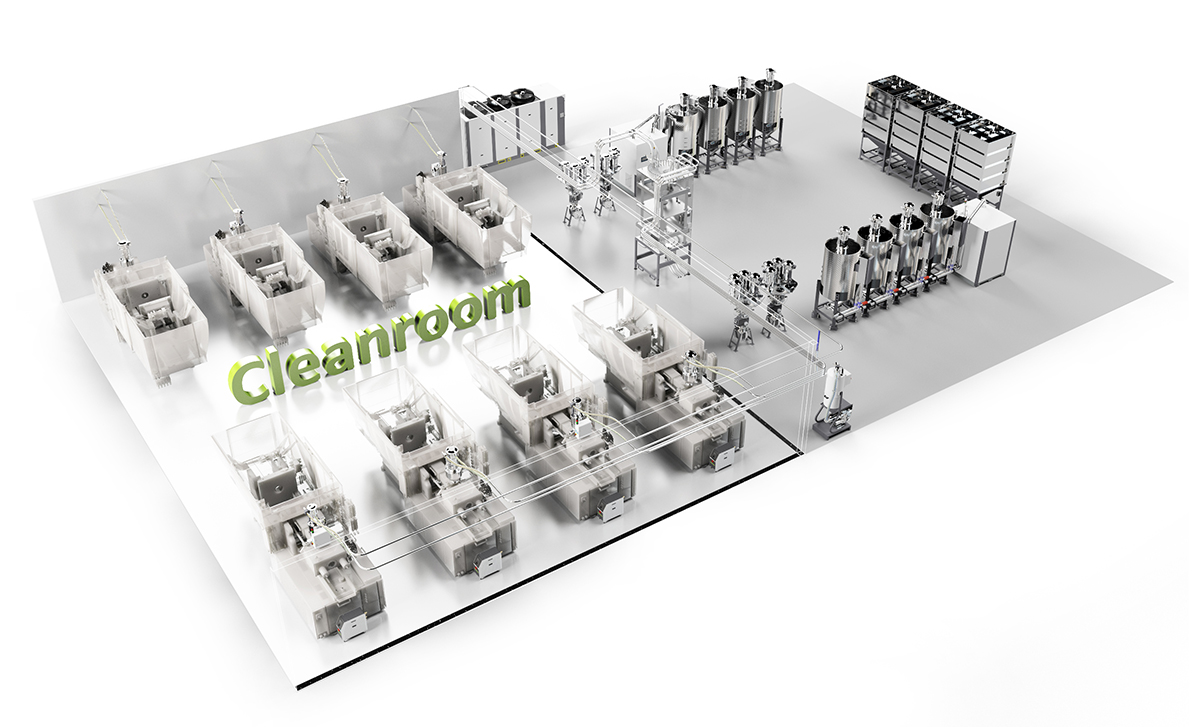

Plastics are essential for medical devices and pharmaceutical packaging. Traceability, cleanliness, safety and precision are essential. Minimising the risk of contamination and maximising the quality of finished products, such as syringes, blister packs, cannulae, blood bags and pipes, fittings and cleanrooms, is therefore crucial in any type of production process: injection molding or high-precision blow molding.

The Piovan Group has consolidated experience in the field of medical applications, thanks to which it is able to supply complete turnkey industrial automation systems for the processing of polymers. The solutions proposed ensure that the physical properties of the polymers remain unchanged during the production process and guarantee complete traceability of both the batches processed and the materials used for the automation system. Piovan has, in fact, developed Winfactory 4.0, the control and management software of the production process designed for the supervision of the digital factory.

GMP is a single or multi hopper drying system, that can adapt and automatically control operating parameters, such as temperature, dew point and flow rate of the process air, according to the production detected. The GMP range is available in 3 configurations: SMART, PLUS and ADAPTIVE. In case of many different raw materials to dry, one GMP dryer can be combined with a multi-hopper system.

The F series vacuum units are characterised by low noise level, up to 75 dB(A), and compact footprint. The F series vacuum units are available in two versions (side channels or claw pump): this allows always the best technical solution for the specific need. Such design makes them suitable for standalone installation beside the IMM and centralized feeding systems or to feed systems with medium to high pressure losses and high kg/h throughput.

Easylink+ is the Piovan automatic coupling station able to manage up to 60 inlets/outlets with pipe size from 40 to 76 mm with minimum footprint. Designed for easy maintenance, it is totally safe for the operators both during regular functioning and service activities. The geometries, the advanced cleaning systems and the wear resistant materials assure the constant production quality in most demanding conditions. Easylink+ is available with supporting frame for floor or mezzanine installation.

Quantum are gravimetric blenders suitable for all plastic materials, immune to vibrations and easy to use. All the surfaces that come into contact with the process material are stainless steel and can be used in the most critical environments, like the medical and food packaging sectors. Its semispherical shape assures perfect mixing without stagnation. The range can have up to 6 dosing stations, which can be easily removed, for emptying or cleaning. The mixer, which can be installed remotely over the processing machine, assures the best mixing, especially after conveying of materials with different densities over long distances.

Ryng is the best solution for real time production monitoring and the usage of raw material. It integrates a high precision load-cell that measures the weight of material loaded into the receiver. The system precision is 1% in typical installation sites with vibration. All the throughput information are recorded also in Winfactory 4.0, to make possible advance analysis of consumptions and material batch tracking.

Easytherm EP is the new mould temperature control unit characterized by user-friendliness, flexibility and reliability, for injection, blow moulding and extrusion processes. Easytherm EP operates at temperatures up to 180 °C. A new interior and exterior layout, redesigned ergonomic control, coupled with high-end components, characterise a versatile machine that guarantees reliability and long term performances. Easytherm EP is already set up for use in Industry 4.0 environments with a wide range of communication protocols, including OPC-UA platform and is Winfactory 4.0 ready.

DPA Series use compressed air for drying hygroscopic polymers. The running parameters can be easily loaded from the internal database. Thanks to the Material Database, the control automatically regulates the process condition once the material has been selected and the hourly throughput has been set. With the use of desiccant cartridges DPA can reach lower Dew Point values (up to –40°C).

Easycool+ is the air cooled compact chiller that has been conceived, designed and built for cooling in specific industrial processes for plastics.

Flexibility, energy efficiency, reduced footprint and low environmental impact: Easycool+ adds value and reduces the costs associated with the investment.

When processing plastics, the temperature ranges to be maintained for different processes can vary significantly, requiring that the chiller provides different conditions of pressure and flow rate: the flexibility of Easycool+ ensures the best operating conditions are maintained at all times. The optimum temperature ensures the best product quality.

Easytherm EW is the new mould temperature control unit that uses water as process fluid with an open system configuration, for injection, blow moulding and extrusion processes. Easytherm EW operates at temperatures up to 90 °C. A new interior and exterior layout, redesigned ergonomic control, coupled with high-end components, characterise a versatile machine that guarantees reliability and long term performances. Easytherm EW is already set up for use in Industry 4.0 environments with a wide range of communication protocols, including OPC-UA platform and is Winfactory 4.0 ready.

The PTUN drying hoppers can be combined in a multi-hopper drying system in order to guarantee maximum flexibility. Each hopper is equipped with an electrical heater on board. The control allows the setting of a different temperature for each hopper; in this way different materials can be dried at the same time, using the right process parameters for each of them. The process air flow passing through the hopper can be adjusted by the operator or in a fully automatic mode according to the actual production with Modula.

The range of Piovan solutions spans from stand-alone single material loaders to central multiple material systems.

Broad selection of technologies to perform the drying process in the best condition possible for the raw material.

Volumetric, gravimetric, loss-in-weight, continuous or batch, are the technologies implemented in the series of blenders and dosing units of Piovan.

Efficiency of heat exchange and reliability of operation characterise our range of temperature control units.

Wide range of solutions that includes from the small movable storage silos on wheels, up to the external silos to stock tonnes of material. The solutions can be totally tailor made on customer request.

Integration of processes is key to utmost efficiency of operation and highest production output.

The simplest way of measuring AA levels in PET preforms. The Piovan Lab-Tech range allows utmost production monitoring, by providing real time analysis of acetaldehyde content in the PET preforms.

Small, medium and large capacities, with the latest design for size reduction, granulation, recycling devices and accessories, represent the range of equipment of Piovan.

Flexcool solution can use ambient temperature to cool the processing equipment. Such a peculiar strategic feature makes Flexcool ideally suitable to serve sets of injection moulding machines having diverse characteristic, that is, in those working situations where different machines are required to operate at varying processing conditions of temperature, flow, pressure. Flexcool ensures the highest level of control, flexibility and energy efficiency.

With specific skills and deep knowledge of the PET preform production process, we provide customised solutions able to satisfy the specific cooling needs of the PET preform sector.

Our air-cooled chillers provide the ideal cooling solution for a wide range of industrial applications related to the plastics processing and to the food industry.

Our water-cooled chillers provide high quality, operation efficiency, and energy savings for a wide range of industrial applications related to the plastics processing and to the food industry.

Our product range includes a line of thermochillers which have the function to heat and cool the process circuit of injection and blow moulding machines utilized in the plastics processing. Available in the single or dual circuit versions, these machines provide maximum cooling yield with minimum energy consumption.

Efficiency of heat exchange and reliability of operation characterise our range of temperature control units.

Our dry coolers are the best answer to the needs of various industrial processes and applications where it is essential to constantly cool the fluid used for the heat exchange at a temperature greater than or equal to that of the external environment. Representing an effective alternative to cooling towers with low costs and low energy consumption.

A very high attention and considerable importance is given to pumps, the devices that allow cooling and chilled water circulate throughout the circuit.

Piovan develops all software for the entire line of industrial cooling solutions.